|

Graver Blanks

Carbalt™

Carbalt is not recommend for hammer/chisel

method of engraving. If hitting with a hammer HSS or M48

is recommended.

Grinding Gravers Precautions |

Carbalt®

3/32" square" x 2-3/8"

(.094" +-.001")

$19.75 each

5 pack $98.75

2 pack $39.50

Note: These Carbalt blanks

are not tapered. The various Lindsay sharpening templates have

built in tapering facets which are used to bring the tip down to

the desired size. A point can be shaped to a small tip using

sharpening templates. A time saving option are the 3 variations

of tapered Carbalt blanks offered below. Yet another option is

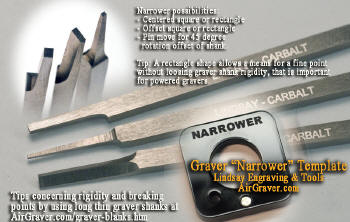

the "Narrower" template ($8) which has customizable options to

taper and thin a graver shank before sharpening.

The photo below illustrates three thinning techniques with the Narrower

template

$8.00

Click to enlarge.

|

One Presharpened

Carbalt®

This is a presharpened

carbalt graver with the 116 degree

Uniform Parallel Point™

that will be sharpened

using the Universal template.

|

One Presharpened

Carbalt®

$46.50

|

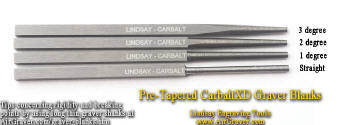

Tapered Carbalt®

Blanks

Available in the following

tapers

Straight

$140 five pack

1 Degree $130

five pack

2 Degree $130

five pack

3 Degree $130

five pack

Get three pieces

of 3 degree and two pieces 2 degree (total five) $130

Note: Rather than purchasing the

above tapered blanks a very fine tapered point can

be made yourself by using the small template . In

other words these pre-ground tapered gravers are not needed to

make a fine tapered point. What they do for you though is

it means there is less bulk for you to remove while using the

small template. Click

photo to enlarge.

|

Click photo to enlarge

View the information and tips concerning

rigidity and breaking points if using thin graver shanks on the

Graver blanks page.

Note: The 3 degree or 2

degree taper is recommended over straight or 1 degree tapers. If new to

engraving stick with the 3 degree to keep the rigidity in the

shank while learning. The straight and 1 degree are for

advanced engravers as they are delicate and can snap in half.

There is no warranty on a snapped in half graver. Tapered shanked gravers are more durable. |

|

M48

-NEW-

3/32" square x 2-1/2"

(.094" +-.001")

$12.00 each

5 pack $60.00

Grinding Gravers Precautions |

|

|

M42 - (Notice: M42

have been replaced by M48 that is more durable than M42)

3/32" square x 2-1/2"

(.094" +-.001")

5 pack $60.00

Grinding Gravers Precautions |

|

|

High Speed Steel

3/32" square x 2-1/2"

(.094" +-.001")

$9.78 each

5 pack $48.90

Grinding Gravers Precautions |

|

|

Colored

graver beads

Slip these over

your graver to help identify

your various graver point. (Graver in photo not included)

|

These are free when placing an order with something else on

the website. During checkout just write a note that you would like a

bag. Otherwise, they can be ordered by themselves below.

Random

colored graver bands. Approx 15 to 25 in a bag

$0.00

|

|

Anti-MagLap

Spin this lap to demagnetize gravers or other small

metal objects. To use, hold the object to be demagnetized close

to the center of the spinning lap and pull the object straight

away from the center.

Forum thread about the Anti-MagLap

|

Comes with a 1/2" hole in the center so

that it can be mounted on a power hone. Or it can be mounted on

a "mandrel lap adapter" (sold above) so that a drill press or

electric hand drill can be used to spin the lap. Big thank you

to Paolo for his contribution and help with this lap!

Anti-MagLap

$46

|

|

|

Practice

Ring Blanks

These proprietary alloy ring blanks engrave and drill clean. No stick

or gummy cutting.

Set of three

with widths of 6mm, 4mm and 2mm. Price works out to $5.78 each, but

they are only sold in these three piece sets.

$17.35

|

|

Graver narrowing tips

A long, thin shank can be useful, but there are

drawbacks as well.

The bright side is that there is less material to grind away when

sharpening, and that the view is less obstructed when engraving.

The disadvantage of a narrow shank is the lack of rigidity. An

experienced engraver comes to realize that the object being

engraved needs to be held securely in a vise to get the best

results. If there is any recoil movement, things get difficult.

The metal will seem to cut harder and more broken points will

occur. The same principle applies to your cutter. When a long,

thin graver is used with a power assisted graver, it will flex or

vibrate with the result of power loss and more broken points. A

thicker, shanked graver can make noticeably cleaner cuts than the

same point on a long, slender shank when used in a power graver.

That said, the effect is less pronounced when cutting fine lines.

A means for having a balance of both rigidity and a small tip is a

taper rectangle shaped shank (similar to a knife blade). The

"Narrower" template works to grind such a shank accurately.

|

Graver Material Comparison Chart

| |

HSS |

M42 |

M48 |

Carbalt® |

| Pros |

Durable, less likely to break. Less expensive |

Harder than HSS and holds a cutting edge

longer while still maintaining good durability for less point

breaking. Less expensive than Carbalt®. |

Balance between

M42 and Carbalt® |

Harder than M42 and HSS. More durable than straight carbide gravers. Holds up in harder metals, stainless, gun and knife

metals with stronger ground geometry. Cutting edge holds up longer than HSS or M42 without going dull. Engraving in brass, gold, silver, and platinum

maintains a polished cut without galling. |

| Cons |

Cutting edge wears faster than does M42 or

Carbalt®, thus requiring more frequent resharpening. When used

to engrave in brass, gold, silver, and platinum, HSS does not cut as

bright compared to Carbalt® gravers. |

More expensive than HSS. Engraving in brass, gold, silver, and platinum do not cut as bright compared to cuts using

Carbalt®.

|

Balance between

M42 and Carbalt® |

Most expensive. More likely to break than go dull. Not recommend for narrow fragile geometry ground points in harder metals.

Carbalt is not recommended for hammer/chisel method of engraving, or

used with a Nitro AirGraver that is too powerful and can break

Carbalts in half. For these methods of engraving HSS or M48 is

recommended. |

| Uses |

Good for making points that are narrow and fragile, such

as undercut gold inlay gravers, narrow flats and Vs. In years past used by

many engravers as an all around less expensive graver. |

Same as HSS but all around improvement in

terms of holding an edge longer without becoming dull as easily as HSS. |

Balance between

M42 and Carbalt® |

In harder metals Carbalt® is great for stronger shaped geometry such as Lindsay Uniform-Parallel points, 96 degrees and wider.

To increase strength of a point dub the face to effectively place a small steep face right at the tip.

Points with weaker geometry can be used in softer metals such as gold,

silver, copper, etc. |

Note: It has come to our attention that some inferior tool blanks are being offered by others. These blanks may be seriously undersized and

therefore may not sharpen properly in the Lindsay sharpening system. It has been noted by some of our Lindsay tool users that they may wobble slightly in the

holder, causing difficult cutting, especially of fine shade lines. By contrast Lindsay blanks are manufactured to precise tolerances to within +- .001 inch of the

3/32 inch specifications. We must warn our users, to insure proper function of your Lindsay Sharpening system, and Lindsay air tools, be sure to use authentic

Lindsay Carbalt™, M42 and High speed tool blanks. Accept no substitutes!

Graver grinding and heat

information

Lindsay Carbalt™ has gotten even better. Lindsay

Carbalt™ is more durable than the original plus they are longer. The gravers are fine-grain carbide and cobalt. The grade was

developed in close collaboration with several carbide manufacturers for the specific use of hand engraving and impact resistance. These gravers can be ground and

shaped with either a silicon carbide grinding wheel, a diamond grinding wheel or a diamond hone. When rough grinding, if the material becomes hot, DO NOT quench in

water. Heat (up to 1500F) will not anneal or damage Carbalt as it does HSS,

M42, or tool steel, but quenching while it is hot may cause it to become brittle causing the point of the graver to break more easily during use.

Carbalt can be ground and gotten very hot on a high speed grinder like the TW

Design variable high speed hone without damaging it, however, again do not

quench it in water if you do get it hot.

Water should be used to keep

the heat down on HSS and M42 or set on a low speed with the

TW Design power

hone. Do this

by grinding until the surface being ground becomes only warm to the touch and then dip in water. There may only be a second or two of grinding between dipping, but

keep dipping in and out of the water during grinding. This will keep the graver from getting hot, assuring the material does not become damaged. The type

of grinding that builds up heat is usually done to rough the graver blank to shape. For final shaping and sharpening use a diamond lap either by hand or with

a slow speed power hone which will not cause excessive heat.

Graver grinding,

Heat build-up and resharpening.

By Steve Lindsay

I receive questions about

graver materials, heat build while grinding, reshaprening and hope this

information will help.

Carbalt (Carbide) can take heat more than HSS or M42. For example I sometimes

make carbide tipped boring bars by brazing or silver soldering (around 1400F) a

piece of Carbalt to the end of a bar. This is then used for boring an accurate

I.D. in the lathe. One thing you do not want to do with carbide if you'd gotten

that hot by brazing or grinding hard on a high speed grinder is quench it

in water. Let the carbide air cool. A large thermal shock could damage it. I use

a Tom White's (TW Design) variable

speed power hone (0 to 3000rpm) for grinding at full speed for grinding the

presharpened Carbalt gravers that we send out with each AirGraver purchase.

These are rough ground from blank in 2 to 2.5 minutes including finishing. The

finishing it done by immediately going from the high speed roughing to a 2000

grit diamond bench stone to clean up the face and place the two heels on.

If I am bright cutting and want to polish the graver up further I then go to the

ceramic bench stone with 50,000 grit diamond. There is no need to

polish if you are engraving a gun/knife or jewelry that you plan to blacken in

the engraving. On my engraving bench I just have a 2000 diamond

bench stone for touching up broken or a dull point. I just keep the large

template on the sharpening fixture. When the point breaks remove it from

the AirGraver, place in the sharpener, rub the face 2 to 10 strokes depending

how bad it is broke, then rotate the fixture over in your hand and do a stroke

or two for each heel. In other words there is no need to go back to

a coarser diamond stone than the 2000 or to the power hone for repairing a

point. I also have 3000 diamond bench stones available. They are not

on the site, but if you'd like one order a 2000 diamond bench stone and write a

note in the space provided for a note when you check out that you'd like a 3000

diamond stone. Price is the same for the 2000 or 3000. The

sharpening fixture, templates and diamond bench stones

can be found at this link.

HSS or M42 graver blanks require more care in grinding than Carbalt: not to let

them get too hot. I also rough sharpen HSS graver blanks on the TW grinder for

the presharpened graver that ships with the Nitro AirGraver

handpieces. I keep them cool by grind

for maybe 10 seconds, quenching

in wather, grinding 10 seconds and quench..etc. You can monitor with your

fingers also. You want to

monitor to be careful not to

turn it colors. With HSS you will start to draw the hardness back at around 700

degrees. (a little past blue

color) In contrast carbon steels (i.e. W1, O1, A2, D2, 440C) you will start to

draw the hardness back at around 300 to 400 degrees. (faint straw color)

There is good info about

carbide compared to HSS in cutting tools on Wikipedia.

https://en.wikipedia.org/wiki/Tungsten_carbide

"Sintered tungsten carbide cutting tools are very abrasion resistant and can

also withstand higher temperatures than standard high speed steel tools.

Carbide cutting surfaces are often used for machining through materials such

as carbon steel or stainless steel, and in situations where other tools would

wear away, such as high-quantity production runs. Because carbide tools

maintain a sharp cutting edge better than other tools, they generally produce

a better finish on parts, and their temperature resistance allows faster

machining."

Graver Grinding and Dust

Precautions should be taken when grinding high

speed steel, tool steel, carbon steel, tungsten carbide gravers. Dust

from grinding metals can cause nose, throat, skin and eye irritation and

temporary or permanent respiratory disease in a small percentage of exposed

individuals.

Take the following safety precautions:

1. If using a diamond lap, coat the lap with oil

or water to keep the grinding dust from becoming airborne.

2.

Wash hands after grinding and before eating or smoking

3. Clean up grinding dust with wet paper towels or rags and discard of properly.

Health Risks download Safety Data

Sheet Cemented Tungsten Carbide

|